Main points of installation and maintenance of PE ball valve

- Categories:3)Installation and maintenance

- Author:

- Origin:

- Time of issue:2020-03-20 15:27

- Views:

(Summary description)The valve shall be placed in the shade of the site for a period of time before installation so that the temperature of the valve is basically the same as that of the pipe. Valves and pipes shall be pr

Main points of installation and maintenance of PE ball valve

(Summary description)The valve shall be placed in the shade of the site for a period of time before installation so that the temperature of the valve is basically the same as that of the pipe. Valves and pipes shall be pr

- Categories:3)Installation and maintenance

- Author:

- Origin:

- Time of issue:2020-03-20 15:27

- Views:

(1)The valve shall be placed in the shade of the site for a period of time before installation so that the temperature of the valve is basically the same as that of the pipe. Valves and pipes shall be protected from sun exposure, and the temperature in installation and use shall have no great difference as far as possible, so as to reduce the influence of temperature difference stress on valves.

(2) When the valve is unpacked, the welding area shall be kept clean and the pipeline shall be purged clean. Welding with the pipeline is needed when the valve is fully opened. During installation, the connection pipe of PE ball valve must be coaxial with PE pipeline, and the valve stem should be in a vertical state to ensure the normal operation of closing and opening PE ball valve.

(3) The compactness of backfill soil meets the requirements to avoid uneven settlement.

(4) It should not participate in purging nor purge the endto avoid purging debris accumulation in the valve core and destroy its sealing performance. The diffusing device is used for replacing and sampling the gas and other gases through PE pipeline, and should not be used as an air outlet for pipeline purging or an air inlet for strength test and leak test.

(5) For the installed PE ball valve, whether the PE ball valve is running online or not, it should be opened and closed several times at intervals of 3-6 months to make the PE ball valve in a smooth and normal good state. During the closing and opening operations, the operating lever shall be in a vertical state, with steady force and operation in place.

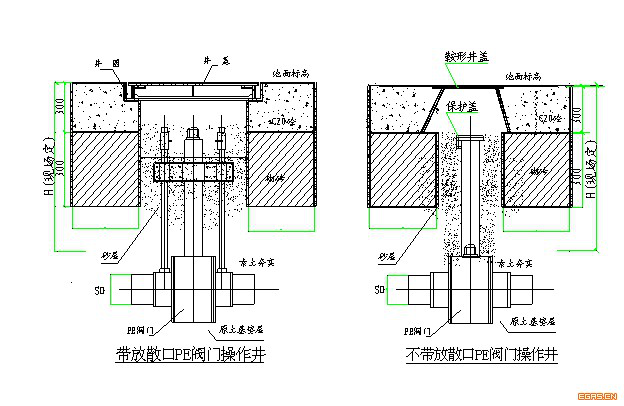

(6) Masonry of valve chamber and PE gas valve can be directly buried, but for relief PE gas valve or valve set on cement pavement, valve shaft should be set to facilitate valve operation and maintenance. The valve and chamber frame must be located in the compacted soil layer. If it is a loose soil layer, it must be tamped in layers. The thickness of each layer shall not exceed 20cm, and its compactness shall not be less than 95%. The valve shall be installed after the cushion layer reaches the strength. Good sand shall be filled around the valve and tamped in layers. The operation well requires that a wall with a width of 240mm and a thickness of 30cm be built before C20 reinforced concrete with a thickness of 30cm is built. In addition, in order to avoid UV damage to the valve in the exposed air, it is recommended to use high-quality fine sand cover on the upper part of the valve.

Internal leakage of ball valves. Users in some areas experienced internal leakage after using PE ball valves for several years. The manufacturers inspected the replaced valves and found that most of them were caused by too dirty pipeline mixed with sediment, and sediment accumulated on the valve core, which affected the use of the valve. Some even scratched the valve core. The reason was that the pipeline was not purged properly at the end of the pipeline construction, or the pipeline gas was not clean, or even purged after the valve was installed, resulting in sediment accumulation in the valve cavity. These did not meet the requirements of relevant national technical specifications for gas transmission and distribution. Therefore, internal leakage would not occur as long as the construction was standardized, and the gas supply conditions were improved.

Scan the QR code to read on your phone

Contact us

Beijing songtiancheng technology co. LTD

Add: no. 7 xingyan street, yancun town, fangshan district, Beijing

Tel: 010-80330935

Mail editor: 102412

Mailbox:market@bjstc.com

Web :www.bjstc.com

Online message

Beijing songtian cheng technology co., LTD 京ICP备 19013408 号 website construction: zhongqi power north dichotomy